Heating or steam boiler systems in North Rhine-Westphalia

Operators of heating or steam boiler systems in North Rhine-Westphalia can participate under certain conditions in the Joint Implementation (JI) model project JIM.NRW by investing in the installation of energy-efficient or renewable boilers and selling the CO2 emissions saved as verified emission reductions or emission reduction units (ERUs) via the North Rhine-Westphalia Energy Agency. The aim of the model project is to cover the investment costs incurred through the sale of ERUs instead of state subsidies. Bundling the measures simplifies the administrative effort and reduces transaction costs, thus making participation in emissions trading also possible for organisations such as kindergartens and schools.

As an official JI project under the Kyoto Protocol, it is ensured that the emission reductions taking place cannot be used simultaneously to achieve Germany's national emission reduction targets and at the same time to generate additional ERUs. The danger of double counting is thus excluded.

Examples of participating institutions in this project are:

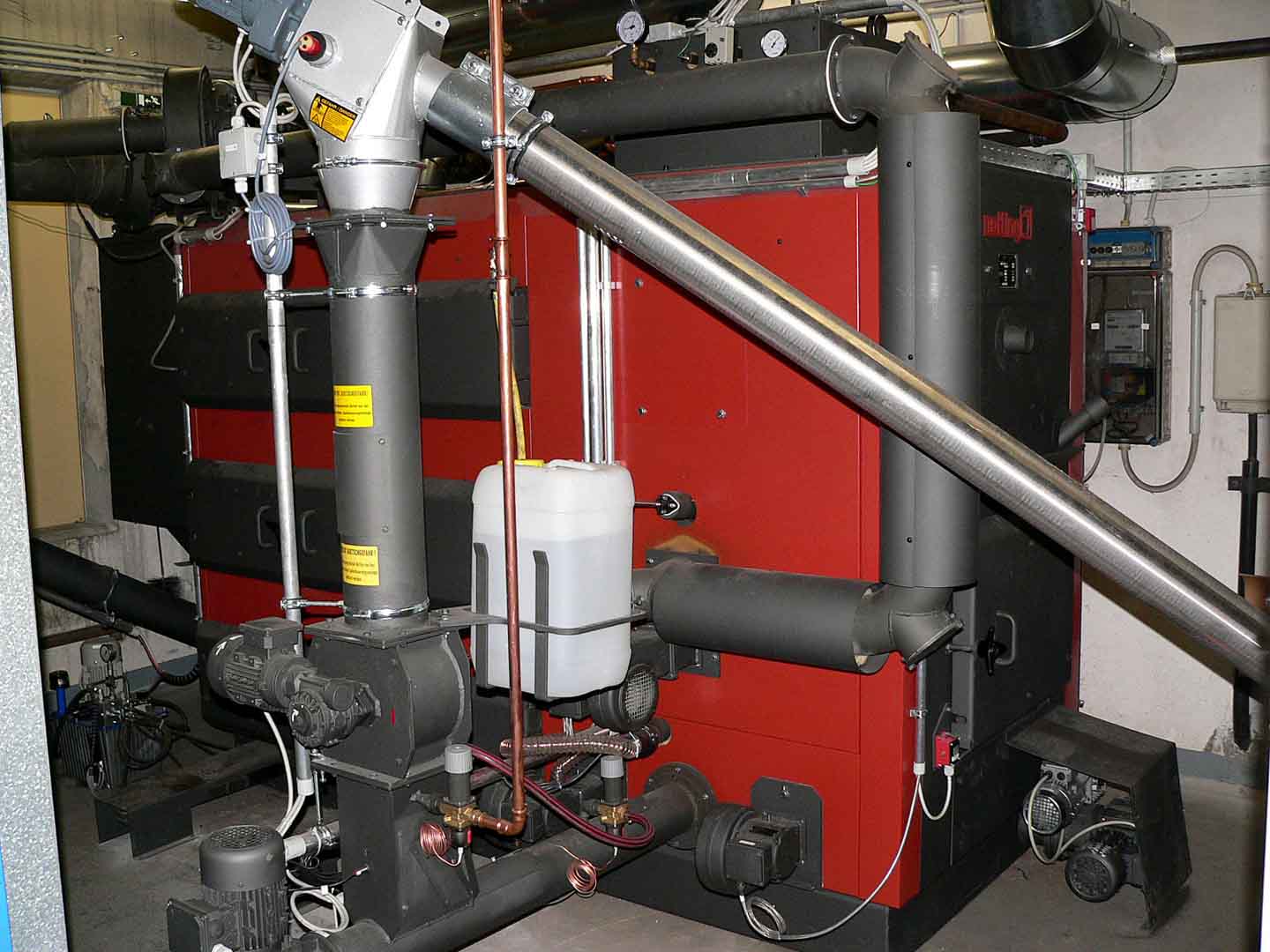

- School Centre South in Neuss: Replacement of heating system with wood pellet system (annual saving of 300 t CO2 emissions)

- Day care centre in Hoerstgen, Kamp-Lintfort: Replacement of coal-fired boiler system with biomass heating system (annual saving of 80 t CO2)

- Horticulture company Schräder, Münster: Replacement of oil-fired boiler with wood-chip boiler for vegetable cultivation in a greenhouse (annual saving of 630 t CO2)

- Residentual quarter "Am Morgensteig", Essen: Installation of a new wood pellet system to supply heat to 205 flats in 41 houses (annual savings of 290 t CO2).

Four criteria for projects to meet quality thresholds

The life cycle of a climate project

A climate project has a set life cycle consisting of various phases, from the feasibility assessment to the retirement of Verified Emission Reductions (VERs).The project developer reviews the general feasibility of the project, the project design, and the financing. Then, the Project Design Document (PDD) is prepared, which contains all the basic information about the project, such as the objective, location, timeline, and duration.

In this phase, independent auditors examine the PDD and the information it contains. This phase often also involves field visits with on-side interviews and analyses. Auditors are accredited, impartial assessors who have to be approved by the relevant standard as a validation and verification body (VVB). TÜV Nord/Süd, S&A Carbon LLC., and SCS Global Services are examples of VVBs."

Once validated, the project can be registered with a standard such as the Verified Carbon Standard or the Gold Standard. All high-quality climate projects are based on international standards. They provide the framework for project design, construction, carbon accounting, and monitoring. Recognised standards make the climate project system and the projects themselves resilient, traceable, and credible.

After the climate project has been registered, the monitoring begins. Here, the project developers monitor and document the data of the project activities and progress. The duration of the monitoring phase varies from project to project: it can cover two years, but documentation over five or seven years is also possible.

At the end of each monitoring phase, a VVB checks and assesses whether the values and project activities stated in the monitoring report are correct. As with validation, visits to the project site are often part of the verification process.

Once verified, the emission reductions that were confirmed in the verification phase can be issued as VERs. The steps of monitoring, verification, and issuance of VERs are repeated regularly and are therefore considered as a cycle.

Once a VER has been used, it must be retired. This process is also reflected in the registry. If the financing of a climate project is done through ClimatePartner, the VERs are bundled in a system certified by TÜV Austria and then retired on a regular basis. This ensures that each VER can no longer be sold and is only used once, preventing double counting.

Explore our projects

Biochar for Climate Action, Healthy Soils, and Better Harvests

A certified climate project combined with additional commitment

Expansion of renewable energy generation in Asia

Ceramic water filters save CO2 and improve health

Improved cookstoves worldwide – for better health and cleaner air

A certified climate project combined with additional commitment

Powering access to renewable energy in Africa

A certified climate project combined with additional commitment

Restored ecosystems remove carbon

Turning degraded farmlands into healthy ecosystems

Improved cookstoves - better for health and the environment