Better cookstoves for a better life

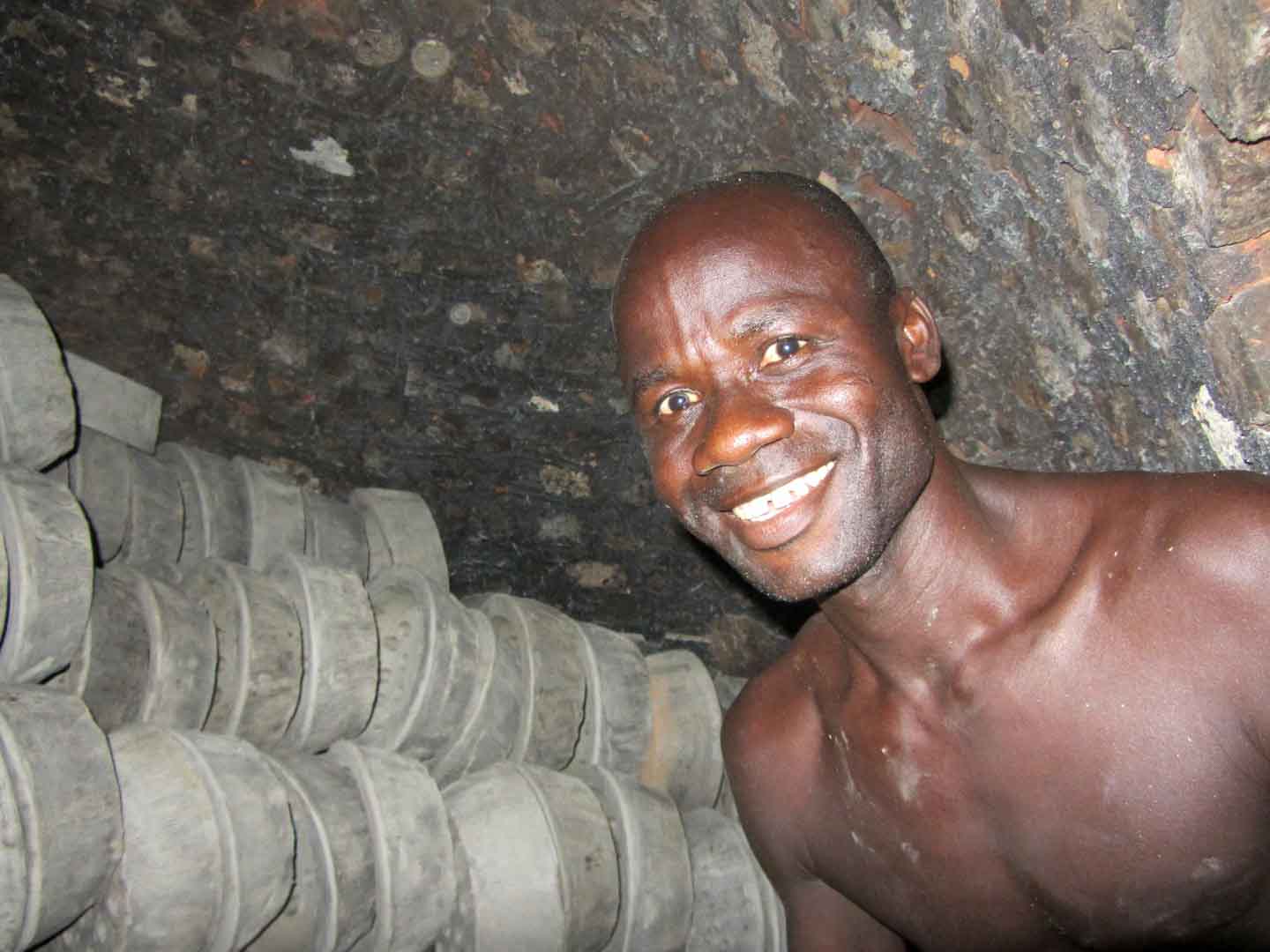

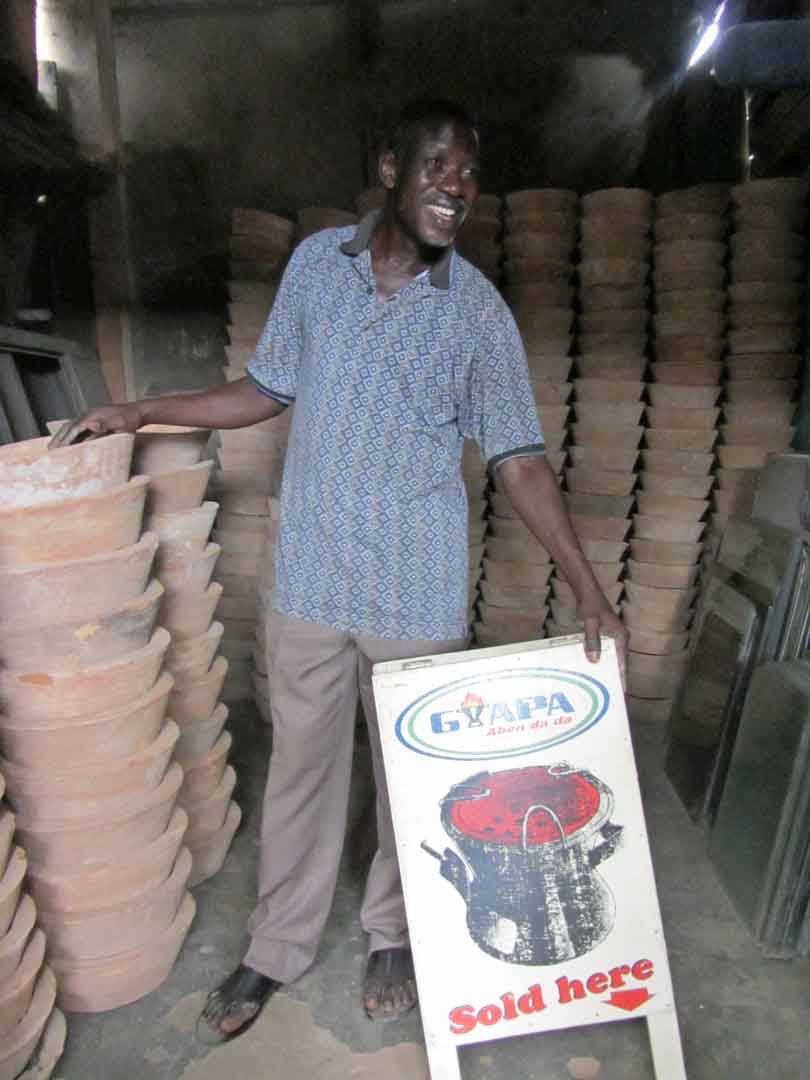

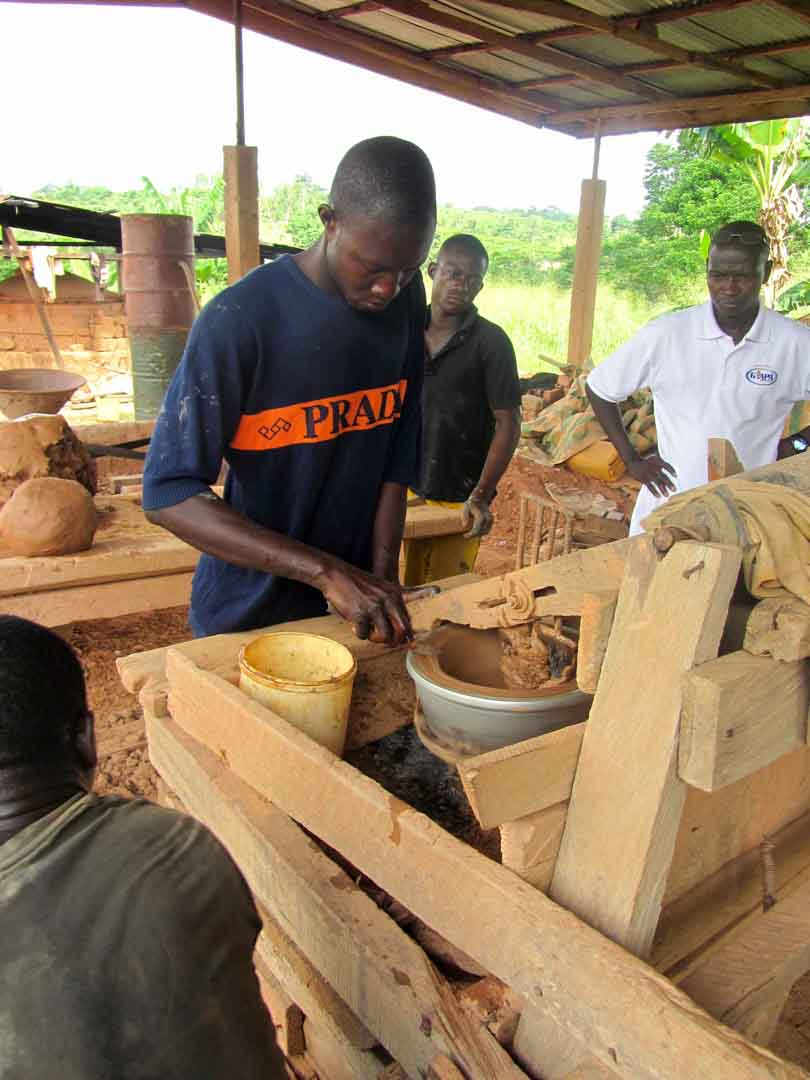

In Ghana, most families traditionally cook with wood or charcoal on inefficient stoves called "Coal Pots". High fuel consumption is one of the main causes of deforestation. In addition, charcoal is produced in a simple and emission-intensive way. The Gyapa Improved Cookstove Project replaces the traditional inefficient charcoal stoves with efficient Gyapa stoves. These stoves can absorb and store heat much better through ceramic cladding. As a result, they consume 50 to 60 percent less fuel and save cooking time.

In addition to avoiding greenhouse gas emissions, the project makes everyday life easier for the population, for example by significantly improving air quality in the houses which benefits women and children in particular. Local manufacturing has led to Africa's largest production of cooking stoves in Ghana. More than 835,000 stoves have already been sold, making everyday life easier for over 4 million people in Ghana.

According to a statistic from the World Health Organization (WHO, 2024) around a third of the global population still relies on unsafe and environmentally harmful cooking methods. This includes, for example, cooking over open fires or using polluting cooking fuels, such as coal or kerosene. Improved cookstoves tackle this problem by using thermal energy more efficiently.

Depending on the model, an improved cookstove can reduce fuel consumption by up to 70 percent, which significantly saves CO2 emissions and can lower the pressure on local forests as less firewood needs to be harvested.

Improved cookstove projects allow the distribution of the - often simple - devices made from metal or clay to households, small enterprises or community facilities. Especially for households, this has an impact beyond the CO2 reduction: better indoor air quality decreases respiratory diseases and families can save time and money as less fuel is needed. Improved cookstoves projects in the ClimatePartner portfolio are registered with international standards.

Four criteria for projects to meet quality thresholds

The life cycle of a climate project

A climate project has a set life cycle consisting of various phases, from the feasibility assessment to the retirement of Verified Emission Reductions (VERs).The project developer reviews the general feasibility of the project, the project design, and the financing. Then, the Project Design Document (PDD) is prepared, which contains all the basic information about the project, such as the objective, location, timeline, and duration.

In this phase, independent auditors examine the PDD and the information it contains. This phase often also involves field visits with on-side interviews and analyses. Auditors are accredited, impartial assessors who have to be approved by the relevant standard as a validation and verification body (VVB). TÜV Nord/Süd, S&A Carbon LLC., and SCS Global Services are examples of VVBs."

Once validated, the project can be registered with a standard such as the Verified Carbon Standard or the Gold Standard. All high-quality climate projects are based on international standards. They provide the framework for project design, construction, carbon accounting, and monitoring. Recognised standards make the climate project system and the projects themselves resilient, traceable, and credible.

After the climate project has been registered, the monitoring begins. Here, the project developers monitor and document the data of the project activities and progress. The duration of the monitoring phase varies from project to project: it can cover two years, but documentation over five or seven years is also possible.

At the end of each monitoring phase, a VVB checks and assesses whether the values and project activities stated in the monitoring report are correct. As with validation, visits to the project site are often part of the verification process.

Once verified, the emission reductions that were confirmed in the verification phase can be issued as VERs. The steps of monitoring, verification, and issuance of VERs are repeated regularly and are therefore considered as a cycle.

Once a VER has been used, it must be retired. This process is also reflected in the registry. If the financing of a climate project is done through ClimatePartner, the VERs are bundled in a system certified by TÜV Austria and then retired on a regular basis. This ensures that each VER can no longer be sold and is only used once, preventing double counting.

Explore our projects

Biochar for Climate Action, Healthy Soils, and Better Harvests

A certified climate project combined with additional commitment

Expansion of renewable energy generation in Asia

Ceramic water filters save CO2 and improve health

Improved cookstoves worldwide – for better health and cleaner air

A certified climate project combined with additional commitment

Powering access to renewable energy in Africa

A certified climate project combined with additional commitment

Restored ecosystems remove carbon

Turning degraded farmlands into healthy ecosystems

Improved cookstoves - better for health and the environment